!!! Our glass is leadless !!!

Glass batch for melting our coloured glass has the same chemical base – except colours No. 200, 200/U, 207, 207/2, 221, 222, 223, OP, OP-M, OP-U, ALB.

Apart from these, all our colours are fully compatible and they can be mixed (fused to alloys).

In case of mixing colours I recommend to read through article (see below): Risk of Mixing Colours.

We deliver glass standardly in cast blocks. Blocks contain bubbles which follows from the processing technology.

| Parameter | Value |

|---|---|

| Leadless glass | 1 melting approx. 250 kg, larger amount after agreement |

| Cast blocks | 20x20x2.5 cm, approx. 2.5 kg +/- 2% |

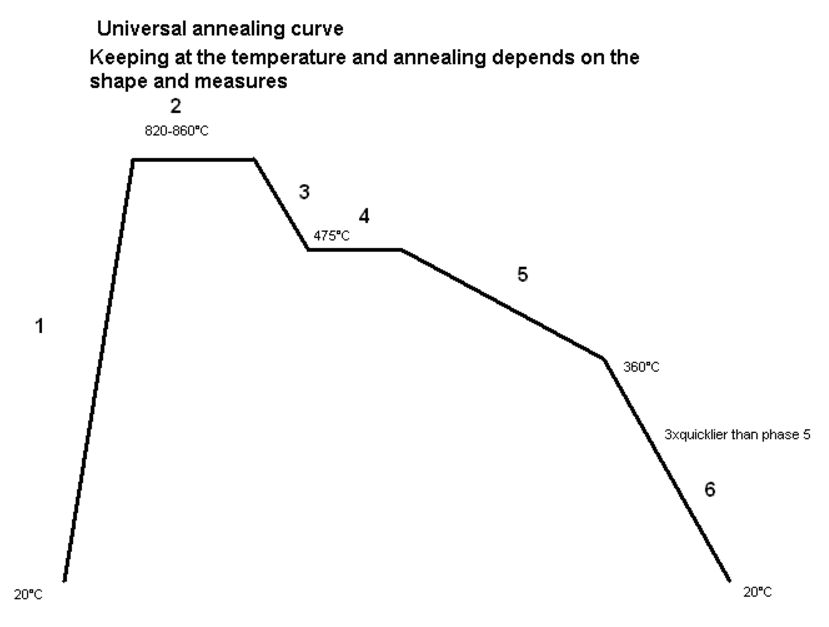

| Melting temperature | 820 – 860 °C |

| Top cooling temperature | 475 °C |

| Deformation point | 545 °C |

| Thermal dilatation coefficient | α 20-300 °C 10 · 10-6 K-1 = 10 COE=101 |

| Specific weight | 2.5 kg/l |

The initial digit in the colour number indicates the group of related colours:

1 . . Crystals (various shades)

2 . . Yellow, Topas, Amber

3 . . Blue, Violet

4 . . Aquamarine

5 . . Green

6 . . Alexandrites, Rose, Red

7 . . combinations of coloured grays (deep toned colours)

8 . . Uranium glass (coloured glass with green ultraviolet effect) – harmless to health

OP Hazed white and coloured Molten glass

Glass with added uranium reacs to ultraviolet component of radiation (sunshine, some halogen bulbs, ultraviolet lamps, fluorescent tubes etc.) and the ultraviolet component thus generates a green reflection effect.

According to the directive of SÚJB (Státní úřad jaderné bezpečnosti, State Authority For Nuclear Safety) glass containing less than 1 % of uranium is not considered radioactive. Such glass does not emit measurable amount of radioactivity and it is harmless in the sense of any exposition.

Colors containing specific oxides are forming crystals in process of melting.

During remelting they change color from violet red more to a shade of brown red.

This is due to the growth of coloring crystals. This process increases with a melting delay at temperatures of 600 to 500 ° C.

You can influence the magnitude of the change to brownish red by quickly overcoming this temperature interval in both directions, ie when heating up and when cooling down.

The crystals grow only in this temperature range.

These colours change shades (from red to red brown) after next melting (casting): 601,602,603,604,607,607×2,608,609,610,813,814,817.

As the technology of production of large glass objects is being developed, large demand arises to combine two or more pieces of glass. The practice of recent years proves that this can be done using glass materials with precise dilatation. Our glass meets these requirements; however, it needs to be said that:

Conclusion: many artists are successfully using multicoloured production of glass objects from our materials and they are able to explain to the customers where the object can be placed so as to minimize the risk of tension due to external effects.

In order to reduce these risks we are developing new glass materials. In 2012 we have managed a small miracle and we have developed : a specific low-dilatable glass EX, which can be used outdoors.

Lenka Čechlovská

Rádlo 256, 468 03, ČESKÁ REPUBLIKA

VAT ID: CZ6009227103

| Item | Value |

|---|---|

| Adresa banky | Česká spořitelna, Mírové náměstí 13, 466 28 Jablonec nad Nisou |

| Telefon | +420 956 734 150 |

| Číslo účtu | 1765041263/0800 |

| SWIFT | GIBACZPX |

| IBAN | CZ25 0800 0000 0017 6504 1263 |

© All rights reserved